Grantlun got us to assess our entire operation (the good and the bad). So far we are having real in-depth conversations as we work through the workbooks and are optimistic we will see real improvement to our quality and bottom line. Great approach, great product and great people.

Grant Lungren’s extensive real world construction experience and technical insight have been an invaluable help to our organization. Grant has helped us streamline our operations and helped us to implement many time saving automated systems. With his help we have trimmed our workforce while growing our revenue. I would recommend Grantlun to anyone that is interested in having a knowledgeable no-nonsense party on their advisory board.

Grant Lungren has been a tremendous asset to our company. He has helped us establish and define our corporate structure as well as aided us in the implementation of business processes that have allowed our company to grow. I personally, rely on him for his knowledge and insight to our industry – someone that I can lean on. We were taught very well how to run the equipment and get the jobs done. We just weren’t taught how to run a business. That’s where Grant comes in!

Grant’s knowledge of systems and procedures and, more importantly, his ‘been there, done that’ experience has helped us navigate the many pitfalls inherent to a growing construction company. In addition, Grant’s many contacts and nationwide exposure allow us to ‘benchmark’ ourselves against similar companies. Grant’s most important contribution has been to help me meet the company’s goals while at the same time meeting my personal goals for a balanced and full life.

Equipment Charge Rate Management

Setting accurate equipment charge rates is one of the most important management chores in a construction company. It’s also one of the most difficult. If you set equipment charge rates too low, you won’t recover the true cost of owning and running your fleet – so job profits will be wiped out by equipment losses. If you set them too high, your cost estimates will be too high and your bid proposals won’t be competitive – so you will lose work, cover less overhead, and generate less profit.

This one-day in-house training session at your facilities provides you the know-how and the tools needed to accurately develop and maintain internal charge rates, estimating rates and billing rates for every machine in your fleet.

Know-how

This training session teaches you the principles and best practices involved in equipment charge rate development, including:

- The 3 types of equipment charge rates.

- How charge rates relate to accounting and estimating practices.

- Charge rate architecture and elements.

- How to accurately estimate your cost for each element.

- Ways to recover equipment management overhead.

- Ways to recover equipment related job overhead.

- How to establish the best fleet composition.

- Ways to decide whether to buy or lease or rent short-term.

- How to audit and maintain charge rates.

- And much more…

Tools

To enable you to proceed immediately with building your equipment rates, you will receive Grantlun’s Standard Equipment Charge Rate Workbook, which enables you to:

- Store machine data.

- All of the pertinent data for each machine in your fleet is located in one easy-to-access, easy-to-update location.

- Perform key calculations.

- By inputting basic data, you’ll end up with accurate internal charge rates, estimating rates, and, billing rates for each machine in your fleet.

- Audit charge rate accuracy.

- The workbook automatically indicates when charge rates need to be raised or lowered to better match cost experience.

- Audit fleet composition.

- The workbook automatically makes buy, sell or hold recommendations for each machine in your fleet, based on limits that you set.

If you elect to purchase it separately, you can also receive our Advanced Equipment Charge Rate Workbook that has all the features of the Standard workbook plus:

If you elect to purchase it separately, you can also receive our Advanced Equipment Charge Rate Workbook that has all the features of the Standard workbook plus:

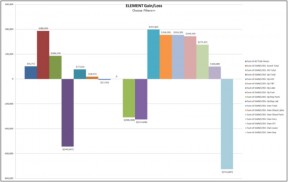

- Pivot Charts that graphically illustrate fleet total and machine specific gains and losses, relative to budgeted costs.

- A ready-made data dashboard that charts each machine in the fleet against all others so that gain/loss outliers can be easily identified and adjustments can be made to the subject machines’ charge rates – or – outliers can be scheduled for repair, rebuild, replacement and rejection.